Page Content:

- What are MOSH and MOAH ?

- The Significance of MOSH and MOAH for the Food Industry

- MOSH / MOAH Regulatory Landscape

- Safety Recommendations & Guidelines on MOSH / MOAH

- MOSH / MOAH Contamination Pathways

- Case Study: Cashews and MOSH / MOAH

- Sources & References

1- What are MOSH and MOAH ?

MOSH and MOAH are acronyms that refer to specific types of substances related to hydrocarbons which can be found in food and other consumer products.[1]

- MOSH stands for Mineral Oil Saturated Hydrocarbons

- MOAH stands for Mineral Oil Aromatic Hydrocarbons

Usually not present in original raw ingredients such as fruits, MOSH and MOAH most commonly enter food through mineral oil contamination across the various production stages (i.e. storage, transportation, processing, packaging, etc.)

Section content:

1.1- Hydrocarbons and Mineral Oils[1][2]

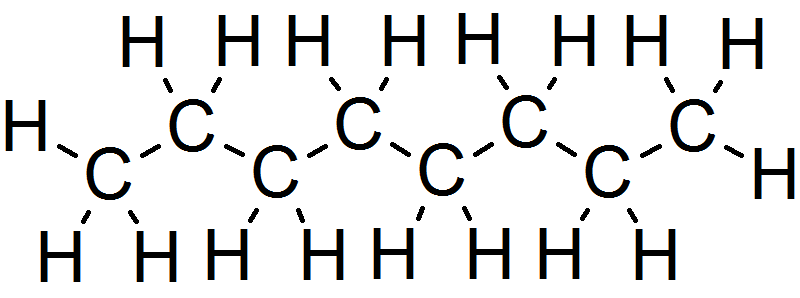

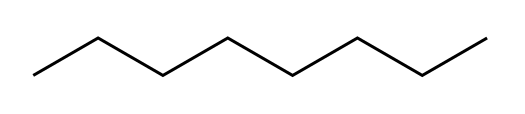

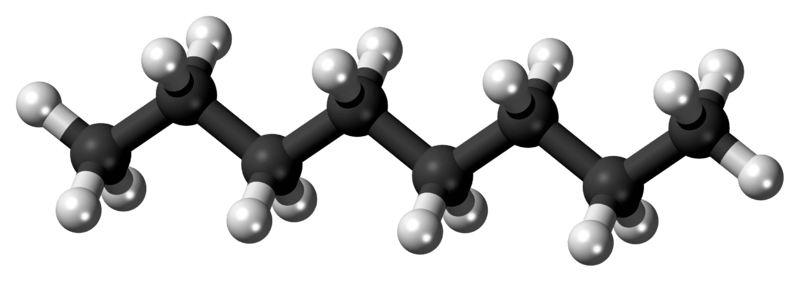

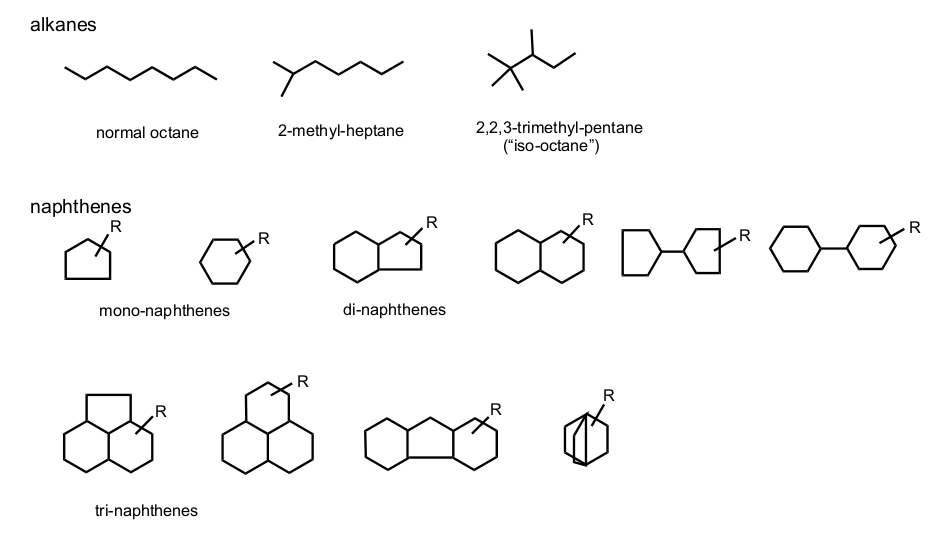

Hydrocarbons are organic compounds consisting entirely of hydrogen (H) and carbon (C). They are naturally-occurring and form the basis of crude oil, natural gas, coal which can be transformed into other hydrocarbons such as Octane.

| Name: | Octane |

| Chemical formula: | C8H18 |

| Molecular formula: | CH3(CH2)6CH3 |

| Structural formula: |  |

| Skeleton diagram: |  |

| Ball-and-stick model: |  |

| Example of Hydrocarbon: Octane (source: wikipedia.org) | |

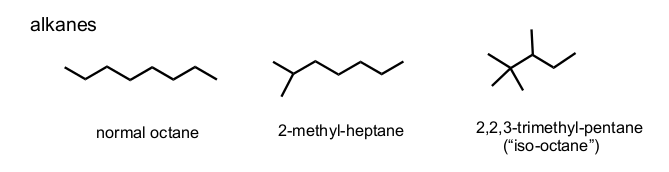

Mineral Oil Hydrocarbons (MOH) are hydrocarbons with 10 to 50 carbon atoms and comprise a wide range of chemical compounds obtained mainly from petroleum distillation and refining.

MOH are divided into two main types:

- Saturated: MOSH (Mineral Oil Saturated Hydrocarbons)

- Aromatic: MOAH (Mineral Oil Aromatic Hydrocarbons)

Saturated (MOSH) and Aromatic (MOAH) mineral oil hydrocarbons are found in various proportions in products such as:

- Fuels

- Solvents (inks, paints and cleaning agents)

- White oils (lubricating and hydraulic oils, release agents, food coatings, additives used in food contact materials, household cleaners and polishes, ingredients of cosmetics)

- Waxes

- Lubricants (vehicles and machinery)

- Extender oils, process or softening oils (used in the production of tyres and other rubber goods).

- Bitumen (road paving)

1.2- Chemical Structure of MOSH and MOAH[1][2]

|

MOSH

(Mineral Oil Saturated Hydrocarbons)

|

MOAH

(Mineral Oil Aromatic Hydrocarbons)

|

|

| Open-chain, mostly branched hydrocarbons (Paraffins) | Cyclic saturated hydfrocarbons (Naphthenes) | Highly alkylated mono-, di-, and higher ring systems |

|

|

|

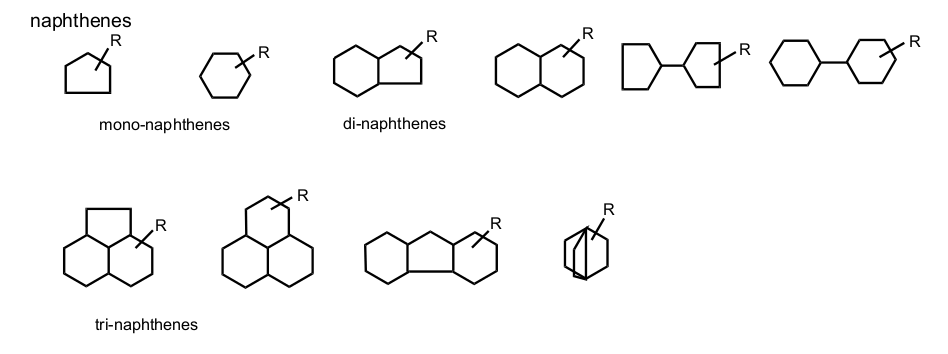

MOSH[1][2]

MOSH refers to mixtures of saturated hydrocarbon compounds that include straight and branched open chain alkanes (paraffins) and non-alkylated and alkylated, mono-, di- and higher cycloalkanes (naphthenes).

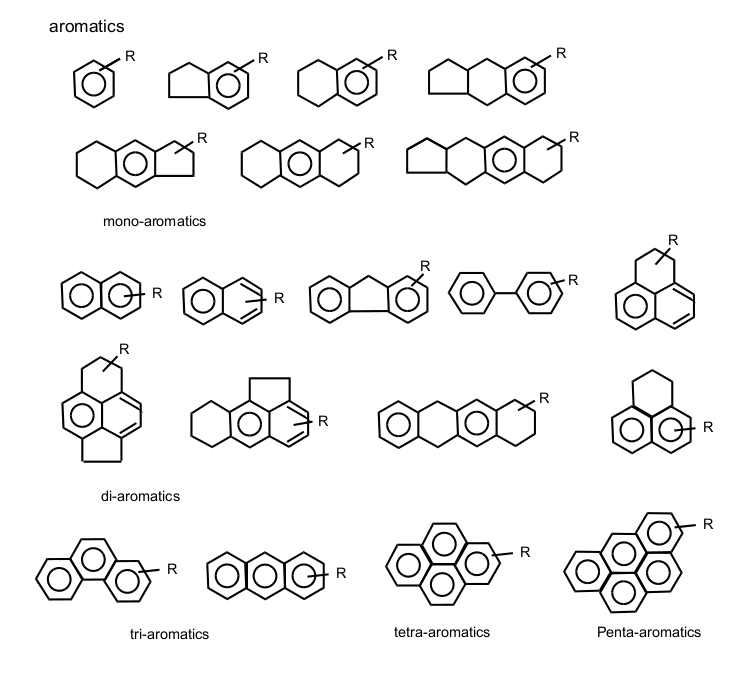

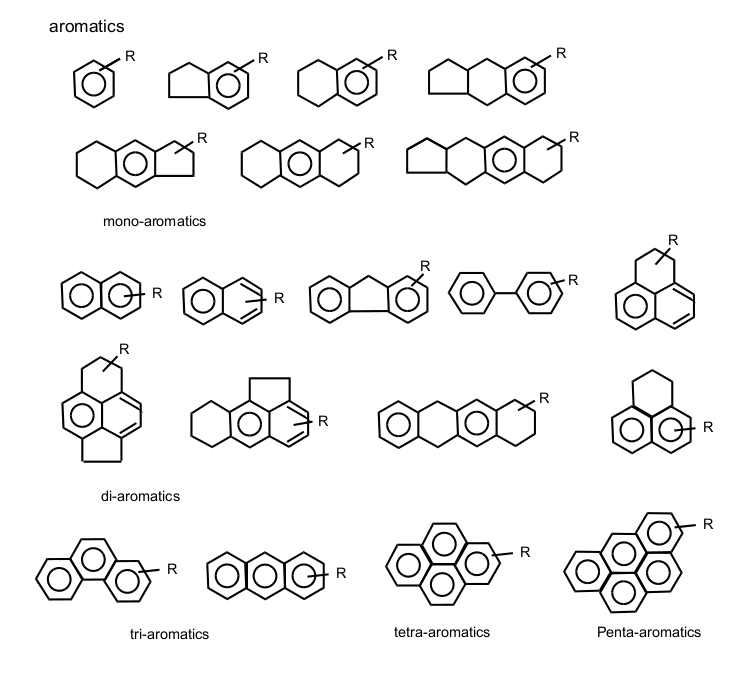

MOAH[1][2]

MOAH refers to a specific class of hydrocarbon compounds called Aromatics.

Aromatic hydrocarbons are characterized by the presence of one or more benzene rings or similar cyclic structures with alternating single and double bonds.

Aromatics can include:

- monoaromatics (single aromatic rings),

- diaromatics (two connected aromatic rings),

- polyaromatics (i.e. higher-ring systems with additional aromatic structures).

Hydrocarbons having at least one aromatic ring are considered as MOAH, even if they are predominantly saturated.

MOAH compounds typically possess one or more aromatic rings and are frequently characterized by high alkylation. These molecular properties increase their chemical reactivity.

Aromatic compounds can be processed by the body and transformed into other substances through metabolic pathways (i.e. metabolised). The propensity of MOAH to undergo metabolism can have implications for their safety or toxicity in biological systems.

1.3- Sources of MOSH / MOAH

The principal sources of MOSH and MOAH contamination are adhesives, printer inks, packaging materials, machine and hydraulic oils, machinery lubricants, and release agents in packaging.

However, under specific circumstances linked to moisture and temperature, part of the lipids naturally present in any oil and fat (including plant- and animal-based) can be transformed into free fatty acids (FFA) and unsaponifiable matter.

Strictly speaking, Mineral Oil Hydrocarbons (MOH) do not include hydrocarbons naturally occurring in food. However, chemically and toxicologically, these hydrocarbons are treated like MOSH/MOAH from mineral oil.

2- Exploring the Significance of MOSH and MOAH For The Food Industry

According to the European Food Safety Authority (EFSA) 2012 report[1], consumers are exposed to a wide range of MOH via food.

Principal sources of MOH in food products are packaging and additives, processing aids, and lubricants. To some accounts, it seems that “you cannot have food free of MOSH and MOAH any more than you could have fat-free bacon”.

Section content:

- The concern with Mineral Oil Hydrocarbons (MOH)

- What are the potential health risks associated with MOSH and MOAH

2.1- The concern with Mineral Oil Hydrocarbons (MOH)

The ubiquitous presence of MOH in food products is a concern in the food industry for several reasons:

-

Potential Health Risks: While not all MOSH and MOAH are considered harmful, some fractions of these hydrocarbons, especially certain types of MOAH, have been associated with adverse health effects. These effects may include genotoxicity (damage to genetic material), carcinogenicity (cancer-causing potential), and other potential toxicities.

-

Lack of Clear Regulations: The absence of standardised limits or regulations for MOSH and MOAH levels in food products makes it challenging to establish consistent safety guidelines. The European Food Safety Authority's (EFSA) efforts to fill the regulatory gap are noteworthy. However, as of August 2023, there is no EU legislation on MOSH and MOAH. The EFSA levels are recommendations.[1][2][3][4][5]

-

Consumer Perception: The presence of MOSH and MOAH in food products can erode consumer confidence and raise concerns about food safety. Consumers have become more conscious of the potential risks associated with certain chemicals in their food, leading to increased demand for transparency and safer products.

-

Analytical Challenges: Detecting and quantifying MOSH and MOAH in food products can be technically challenging. Analytical methods must be sensitive and accurate to identify these compounds even at trace levels, making quality control and monitoring complex. MOH found in food and considered as contaminants often have similar or identical compositions as MOH authorised for use. Discrimination between them is difficult and often unclear. Toxicological evaluation of mineral oil products problematic due to their often-ill-defined composition. Most oils, however, are treated to remove the carcinogenic MOAH.

-

Food Quality and Shelf Life: MOSH and MOAH can also affect food quality and shelf life. These substances might lead to off-flavours, odours, and changes in food texture, which could impact consumer acceptability.

2.2- What are the potential health risks associated with MOSH and MOAH?

Potential health risks associated with MOSH and MOAH have been a subject of concern and ongoing research, particularly in the past decade.[1]

"The potential risks associated with the presence of MOSH and/or MOAH in food primarily stem from chronic exposure (i.e. cumulative exposure)."[6]

It is important to emphasize that the level of risk depends on several factors, including the specific chemical composition of the MOSH and MOAH present (not all MOH are considered harmful), the quantity ingested, the duration of exposure, and individual susceptibility.

MOSH:

- The European Food Safety Authority (EFSA) has noted that MOSH may accumulate in the liver and the lymphoid system[1]. Over time, prolonged exposure to MOSH, even at low levels, can lead to their accumulation in the body tissues, including the liver, lymph nodes, and adipose tissue, as suggested by a study on rats (F344 rats)[7]. However, the same study also showed decreasing concentrations after depuration.[7]

- In its 2023 update, the EFSA concluded that new evidence indicate that n-alkanes, which were the issue for F344 rats, are not accumulated in human liver therefore are not critical endpoints relevant to humans.[2]

- There is no potential for MOSH to induce developmental and reproductive toxicity.[1][2]

- There is no evidence that dietary exposure to MOSH induces autoimmunity.[2]

- There is no genotoxicity associated with MOSH.[2]

- MOSH in human liver, spleen, lymph nodes and other organs are not associated with adverse consequences.[1][2]

- As compared to the 2012 EFSA opinion[1], the 2023 update[2] notes a decrease in MOSH levels was observed across the different food commodities, which, at least partially, could be explained by the different measures introduced by authorities and industry since 2012.

- Overall, EFSA concluded that the current dietary exposure to MOSH for all age groups raised no concern for human health and further confirmed that MOSH is neither genotoxic nor carcinogenic by oral exposure.[1][2]

- However, more research is needed to understand how consuming foods with accumulated MOSH might affect human health.[1][2] Bioaccumulation, particularly in relation to effects in the liver, spleen as well as immune and nervous system, needs further investigation.[2]

MOAH:

- Genotoxicity: New studies on the genotoxicity of MOAH[2] confirmed the EFSA 2012[1] conclusion that the genotoxic effects were associated with the presence of some MOAH with 3- or more aromatic rings.

- Carcinogenicity: Certain MOAH fractions have been classified as potentially carcinogenic, particularly those with a high molecular weight. These substances could increase the risk of developing cancer, especially if exposure is significant and sustained. MOAH with a high degree of alkylation can act as tumour promoters, and some with less than three rings, like naphthalene, can be carcinogenic via a non-genotoxic mode of action[2][6].

- Organ Toxicity: MOAH exposure might also be associated with adverse effects on specific organs, particularly the liver and spleen. This is especially concerning for the higher molecular weight fractions.

- Fetotoxic and developmental effects were observed in dermal toxicity studies on petroleum products containing three or more ring MOAH.[2]

- Dietary exposure to 1-2 ring MOAH lacks reliable toxicity data, which might raise a concern for human health.[2]

It's important to reiterate that not all forms of MOSH and MOAH are considered equally harmful, and the health risks can vary based on the specific chemical composition and the level of exposure.

EFSA identified 3-7 ring MOAH with no- or low-degree alkylation as the components of main concern regarding their genotoxic and carcinogenic nature.[2][6]

As with many chemical compounds, cumulative exposure is a concern. Over time, exposure to small amounts of MOSH and MOAH from various sources can accumulate in the body. This cumulative exposure might contribute to a higher risk of adverse health effects, even if each individual exposure is relatively low.

"Although mineral oil hydrocarbons (MOH) are ubiquitous in the human diet, data suggest that not many people have liver lipogranulomas, and, according to what we know, they are not a health concern."[8]

Experts recommended to conduct more research to quantify the presence of MOAH in food and its toxicity.[2] It is also important to continue the investigations on the possible long-term effects of MOSH on human health.[2][5]

3- MOSH / MOAH Regulatory Landscape

The lack of uniform limits or rules for MOSH and MOAH concentrations in food items creates difficulties in establishing consistent safety standards. While the European Food Safety Authority (EFSA) has made notable efforts to address this regulatory gap, their work is still in progress leaving the food industry in disarray.

Section content:

- EU Regulations for MOSH and MOAH

- EU regulations on food safety and food contaminants

- Navigating Future Regulations: What to Expect in MOSH and MOAH Regulations

3.1- EU Regulations for MOSH and MOAH[2]

As of August 2023, there is no EU regulation on MOSH and MOAH. We only have the EFSA recommendations[9] which can be used by individual member states to craft their own legislation. But, up to this point, no specific legislation has been proposed by any member states.

There are, however, some regulations on mineral oils covering part of the general problem of MOH.

| Category | Lesgislation | Year | Substances Covered | Specific Measures/Limits |

| Food Packaging | Regulation (EU) 10/2011 | 2011 | White mineral oils, paraffinic, derived from petroleum-based hydrocarbon feedstocks (FCM subst. No 95) | No specific migration limit (SML); restricted by overall migration limit of 60 mg/kg food or 10 mg/dm2 food contact surface |

| Waxes, refined, derived from petroleum-based or synthetic hydrocarbon feedstocks (FCM subst. No 94) | No SML; restricted by overall migration limit | |||

| Waxes, paraffinic, refined, derived from petroleum based or synthetic hydrocarbon feedstocks, low viscosity (FCM subst. No 93) | SML of 0.05 mg/kg food; not for articles in contact with fatty foods | |||

| Food Additives | Regulation (EU) 1333/2008 | 2008 | Microcrystalline waxes (E 905) | Approved for surface treatment of confectionery, melons, papaya, mango, avocado, and chewing gums |

| Pesticides | Regulation (EU) 1107/2009 | 2009 | Paraffin oils with CAS numbers: 64742-46-7, 72623-86-0, 8042-47-5, 97862-82-3 | Approved until 31 Dec 2023; No toxicological reference values or MRLs |

| Regulation (EU) 889/2008 | 2008 | Paraffin oil, mineral oils | Allowed for use as pesticides in specific crops and as co-formulants in plant protection products | |

| Veterinary Medicine | Regulation (EEC) No 2377/90 | 1990 | Mineral hydrocarbons | Allowed for use in veterinary medicine for all food-producing species |

|

Note: FCM - Food Contact Materials, SML - Specific Migration Limit, MRLs - Maximum Residue Levels. |

||||

3.2- EU regulations on food safety and food contaminants

What makes the situation particularly difficult for the food industry is that EU regulations on food safety requirements and food contaminants imply a proactive and cautious stance.

Regulation EC No 178/2002, article 14 states that:[10]

1. Food shall not be placed on the market if it is unsafe.

2. Food shall be deemed to be unsafe if it is considered to be:

(a) injurious to health;

(b) unfit for human consumption.

3. In determining whether any food is unsafe, regard shall be had:

(a) to the normal conditions of use of the food by the consumer and at each stage of

production, processing and distribution, and(b) to the information provided to the consumer, including information on the label, or other information generally available to the consumer concerning the avoidance of specific adverse health effects from a particular food or category of foods.

4. In determining whether any food is injurious to health, regard shall be had:

(a) not only to the probable immediate and/or short-term and/or long-term effects of that food on the health of a person consuming it, but also on subsequent generations;

(b) to the probable cumulative toxic effects;

(c) to the particular health sensitivities of a specific category of consumers where the food is intended for that category of consumers.

5. In determining whether any food is unfit for human consumption, regard shall be had to whether the food is unacceptable for human consumption according to its intended use, for reasons of contamination, whether by extraneous matter or otherwise, or through putrefaction, deterioration or decay.

[...]

In other terms, food is considered unsafe if it can harm health or is not suitable to eat. More importantly, the regulation also considers the build-up of toxic effects and the sensitivities of certain groups of people.

The Council Regulation (EEC) No. 315/93 regarding Community procedures for contaminants in food states that:[11]

Whereas contaminants may enter into food at any stage from production to consumption;

Whereas it is essential, in the interest of public health protection, to keep these contaminants at levels which are toxicologically acceptable;

Whereas further elimination must be carried out whenever it is achievable through good working practices; whereas compliance with such good practices can be efficiently monitored by public authorities, given the vocational training and experience of their agents;

[...]

Article 1:

1. This Regulation concerns contaminants contained in food.

'Contaminant' means any substance not intentionally added to food which is present in such food as a result of the production (including operations carried out in crop husbandry, animal husbandry and veterinary medicine), manufacture, processing, preparation, treatment, packing, packaging, transport or holding of such food, or as a result of environmental contamination. Extraneous matter, such as, for example, insect fragments, animal hair, etc, is not covered by this definition.

Article 2:

1. Food containing a contaminant in an amount which is unacceptable from the public health viewpoint and in particular at a toxicological level shall not be placed on the market.

2. Furthermore, contaminant levels shall be kept as low as can reasonably be achieved by following good practices at all the stages referred to in Article 1.

3. In order to protect public health and pursuant to paragraph 1, where necessary, maximum tolerances for specific contaminants shall be established in accordance with the procedure laid down in Article 8.

These tolerances shall be adopted in the form of a non-exhaustive Community list and may include:

-limits for the same contaminant in different foods;

-analytical detection limits;

-a reference to the sampling and analysis methods to be used.

In simple terms, this regulation addresses contaminants that might get into food products during their production and handling to keep these contaminants at safe levels for public health.

The regulation states that:

- Harmful substances should be minimized

- Good practices should be followed in all stages of food production.

- If a contaminant is at a level that is dangerous for health, the food should not be sold.

- To safeguard public health, maximum limits for specific contaminants should be set. These limits will be established through a specific process and may include distinct levels for different foods, methods for detecting contaminants, and analysis protocols.

Finally, the Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food also states that:[12]

Article 3:

1. Materials and articles, including active and intelligent materials and articles, shall be manufactured in compliance with good manufacturing practice so that, under normal or foreseeable conditions of use, they do not transfer their constituents to food in quantities which could:

(a) endanger human health;

or

(b) bring about an unacceptable change in the composition of the food;

or

(c) bring about a deterioration in the organoleptic characteristics thereof.2. The labelling, advertising and presentation of a material or article shall not mislead the consumers.

In other words, this rule states that packaging and materials used in food production should be food-compliant. They should not let harmful substances contaminate food or impact its taste or odour. Labels and information about these products should be truthful and not confuse consumers.

These pieces of legislation clearly put lots of responsibility on the food distributors (retailers) and, through a ripple effect, on the rest of the food production stakeholders.

As far as we’re concerned, this is a strong incentive for European distributors and retailers to invest in the whole production chain and seek long-term collaboration with quality producers and processors such as Cashew Coast.

In any case, the scientific assessments of the toxicology of mineral oils hydrocarbons (MOH) cannot be ignored.

3.3- Navigating Future Regulations: What to Expect in MOSH and MOAH Regulations?

As of August 2023, the EFSA recommendations are not legally binding, and EU Member States are free to decide whether they will implement the new stipulations or not. While the absence of legislation poses challenges for the food industry, heightened public concern will likely lead to regulatory updates.

Consumer rights organisations, such as Foodwatch, deem the existing guidelines inadequate and advocate for a total prohibition of detectable MOAH levels in all food items.[15] Hence, proactively striving for non-detectable MOAH migration from food contact materials into food might be advisable.

If history is any guide, the regulation of trans fatty acids (TFA) provides a precedent from which we can assume that regulations regarding MOSH and MOAH will evolve.

The European Food Safety Authority (EFSA) first viewed evidence about the health effects of TFA in 2003, and the first scientific opinion surmising that "higher intakes of TFA may increase the risk for coronary heart disease" was produced in 2004 [16] [17]. The introduction of legal limits in 2019 was seen as an effective way to reduce industrial TFA and led to the Commission Regulation (EU) 2019/649, which imposed a maximum of 2 grams of trans fat per 100 grams of fat in food for consumers and retail supply. [18]

An important note for the cashew industry is that the regulation on TFA applies to industrial TFA and excludes “trans fat naturally occurring in fat of animal origin”.

This suggests that the legislation on MOH might take into account naturally occuring forms of MOSH and MOAH.

4- Safety Recommendations & Guidelines on MOSH / MOAH

Section content:

- EFSA Recommendations and Guidelines on MOSH and MOAH

- National & International risk assessment organisations

4.1- EFSA Recommendations and Guidelines on MOSH and MOAH

The European Food Safety Authority (EFSA) has been working to assess the potential risks of MOSH and MOAH exposure and to provide guidance on acceptable levels in food products.

MOSH:

EFSA previously assessed the risk related to the presence of MOH in food in 2012, estimating a chronic exposure ranging from 0.03 to 0.3 mg/kg bw per day for MOSH.[1]

According to more recent research, EFSA found that the Margin of Exposure (MOE) exceeded 1200 for all age groups, except for infants solely fed with infant formula (in this case, the MOEs could range from 790 to 1070 and 680 to 870 for moderate and high consumption levels, respectively). Yet, due to the short period of exposure through infant formula, EFSA determined that these MOEs didn't cause worry.[6]

The "Margin of Exposure" (MOE) is not a definitive safety limit for daily intake (i.e. health-based guidance value, HBGV)[13]. Instead, it is a practical method to assess if current intake levels might be harmful when there is insufficient data to set a safe threshold. A lower MOE means a greater risk, while a higher MOE indicates a lower risk. For substances without enough data to set a clear safety limit, the MOE is typically 100 or more. A MOE is below 100 is considered a health concern.

In general, EFSA's assessment found that the current MOSH intake from the diet across all age groups doesn't pose a health risk. Yet, the potential impact on human health from consuming specific foods (like animal products) that might lead to exposure to accumulated MOSH components has not been studied and remains uncertain.

However, the German Federal State Working Group Consumer Protection (LAV) and the Lebensmittelverband Deutschland e. V. Food Federation Germany jointly recommend the use of "orientation values" as a uniformly used, coordinated assessment basis for the source-independent occurrence of mineral oil hydrocarbons and analogues in foods.[14]

The orientation values are based on a statistically reliable basis of comparable data that LAV/Lebensmittelverband have collected as part of a joint project from June 2016. The values provide an orientation as to which source-independent content of mineral oil-like hydrocarbons in foods of a specific group can be expected with a high statistical probability as a result of good manufacturing practice.

For the product group tree nuts an orientation value of 4 mg/kg was determined for MOSH and MOSH analogues of fraction C10-C50.[14]

|

Product group / Food category

|

MOSH and analogues [mg/kg] (C10-C50)

|

|

Vegetable oils and fats (excluding oils/fats of tropical plants)

|

13

|

|

Bread and biscuits, fine pastries, cereal products and cereal-based products, cereals, rice, pasta

|

6

|

|

Confectionery (sugar confectionery except chewing gum), chocolate and cocoa-based confectionery

|

9

|

|

Nuts, oilseeds, coconut, peanuts and dried fruit, including mixtures thereof

|

4

|

|

Desserts (ready-to-eat) and ice cream

|

4

|

|

Ice cream with fat-based coatings, glazes and couvertures

|

10

|

|

Meat, meat preparations and meat products (including sausages)

|

9

|

|

Fish and fish products (including canned fish in aqueous infusion/own juice

|

4

|

|

Milk and milk products

|

22

|

Common MOH-Benchmark levels – Updated 2021 (LAV and Lebensmittelverband 2021) [14]

MOAH:

Given the carcinogenic potential of certain components in this fraction, it is recommended to limit the exposure to MOAH as much as possible.

The EU PAFF standing committee's summary report[9] delineates the varying maximum permissible concentrations of Mineral Oil Aromatic Hydrocarbons (C 16-C 35) in different food categories, contingent upon the fat content of the respective foods.

- 0.5 mg/kg for dry foods with a low fat/oil content (≤ 4% fat/oil)

- 1 mg/kg for foods with a higher fat/oil content (> 4% fat/oil, ≤50% fat/oil)

- 2 mg/kg for fats and oils (>50% fat/oil)

For the product group tree nuts, the LAV and Lebensmittelverband "orientation values" of MOAH (C10-C50) must not be detectable above a limit of quantification of 1 mg/kg (2021).[14]

MOAH can find its way into food through various sources, such as additives, packaging materials, and manufacturing equipment. These limits pertain to the overall MOAH content in food regardless of its source. Manufacturers must ensure that the cumulative migration of restricted hydrocarbon compounds remains below the specified thresholds.

4.2- National & International risk assessment organisations[2]

The legislation and recommendations regarding mineral oil safety in food demonstrate significant variation and pose challenges for direct comparison due to the inherent complexities of the topic and due to the evolving nature of scientific knowledge.

The lack of standardization becomes evident in the diverse approaches taken by different regulatory bodies and agencies. Factors such as the specified hydrocarbon ranges (e.g., C10-C16, C16-C20), migration limits, and the emphasis on specific fractions (MOSH or MOAH) vary considerably across jurisdictions.

| Organization | Year | Substance | Recommendation/Conclusion |

| German Federal Institute for Risk Assessment (BfR) | 2021 | MOSH (C10-C16) | Maximum migration of 12 mg/kg food (preliminary limit) |

| MOSH (C16-C20) | Maximum migration of 4 mg/kg food (preliminary limit) | ||

| French Agency for Food, Environmental and Occupational Health & Safety (ANSES) | 2017 | MOH | Endorses main conclusions of the 2012 EFSA opinion on MOSH and MOAH, with no refinement based on new evidence since 2012 |

| Dutch National Institute for Public Health and the Environment (RIVM) | 2018 | MOSH, MOAH | Focus on MOAH due to carcinogenic properties; MOSH concerns reduced; MOSH exposure similar to EFSA 2012; MOAH exposure 10-20% of MOSH |

| Food Standards Australia New Zealand (FSANZ) | 2018 | MOSH, MOAH | Quantitative risk assessment not performed due to low incidence of detection; Results summarized in Section 3.3 Previous occurrence data |

| Joint FAO/WHO Expert Committee on Food Additives (JECFA) | 1995, 2002, 2020 | microcrystalline waxes and high-viscosity oils (P100) | ADI of 20 mg/kg bw per day |

| medium- and low-viscosity oils class I (P70) | ADI of 10 mg/kg bw per day | ||

| Class II, III White Oils | Acceptable for previous cargoes; NOAEL of 22 mg/kg bw per day; Overall exposure of 0.4 mg/kg bw per day with MOE of 55 | ||

| International Agency on Research on Cancer (IARC) | 2012 | Mineral Oils | untreated or mildly treated mineral oils classified as carcinogenic to humans (Group 1) |

|

Note: ADI - Acceptable Daily Intake, NOAEL - No Observed Adverse Effect Level, MOE - Margin of Exposure. |

|||

Discrepancies in risk assessments, exposure evaluations, and the absence of standardized quantitative risk assessments contribute to the complexity.

The lack of harmonization in legislation and recommendations on mineral oil safety in food packaging stems from the intricate nature of the topic, the evolving scientific understanding, and differences in risk assessment methodologies among regulatory bodies. This variability underscores the need for collaborative efforts to establish more standardized guidelines and promote a cohesive approach to ensuring food safety.

5- MOSH / MOAH Contamination Pathways

The primary sources of MOSH and MOAH contamination are materials like adhesives, printer inks, packaging, and various oils used in machinery. In certain conditions involving moisture and temperature, however, fats in oils, whether from plants or animals, can change into free fatty acids (FFA) and unsaponifiable substances. Due to their chemical and toxicologic characteritics, these substances are considered MOSh/MOAH analogues.

Section content:

- How MOSH and MOAH enter the food production chain?

- Susceptibility of Fatty Foods: Why Oily Foods Are Prone to MOSH / MOAH Contamination

5.1- How MOSH and MOAH enter the food production chain?

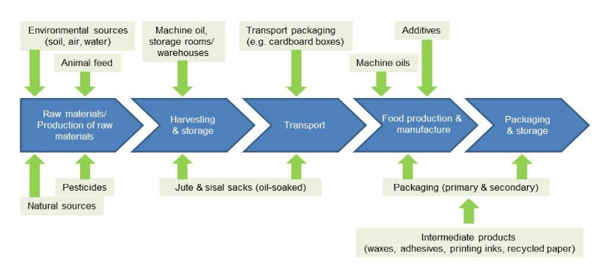

MOSH and MOAH can enter food from numerous sources at various stages of production, processing, and packaging. Potential sources include:

- environmental contamination (air, soil, aquatic),

- lubricants for machinery,

- release agents, processing aids,

- food or feed additives,

- materials such as printing inks and adhesives used in food packaging,

- the use of recycled cardboard can lead to high levels of contamination, both in direct

contact and by gas phase migration [19].

Advanced analytical development with regard to sensitivity and automation means that it is now possible to detect MOSH and MOAH representing less than 0.5 to 1 mg/kg in routine examinations. Thanks to this progress, new sources of contamination are constantly being identified and addressed.[19]

|

Production Stage

|

Source product

|

Possible source of MOSH-MOAH

|

Solutions / Mitigants

|

| Cultivation, agricultural practice, harvest | Jute and sisal bags | Batching oil | Use food grade packaging |

| Exhaust fumes | Harvesters, environment | Avoid direct contact | |

| Storage and transport | Jute and sisal bags | Batching oil | Use food grade Packaging |

| Exhaust fumes | Environment | Avoid direct contact | |

| Container Lining | Recycled corrugated cardboard |

Use virgin fibre or barriers | |

| Production | Machines | Lubricants | Use H1 products |

| Polluted air | Overfilled oil filters | Check and change oil filters regularly | |

| Cleaning supplies | Cleaning supplies | Use food grade products | |

| Package and Storage | Printing Ink, glues, waxes, kerosene oils, labels | Printing Ink, glues, waxes, kerosene oils, labels | Use food grade products Avoid Writing on the packaging with non food grade pens |

| Recycled package | Printing ink | Use virgin fibre | |

| Storage | Multiple | Minimise time and temperature |

Analyses at different steps of the supply chain should be performed to ensure the content of MOH (MOSH MOAH).

It is important to bear in mind that the higher the fat content of a foodstuff, the greater the risk of contamination from MOSH and MOAH.[19]

5.2- Susceptibility of Fatty Foods: Why Oily Foods Are Prone to Contamination

The lipophilic or "fat-loving" properties of certain foods such as palm oil, olive oil, sunflower oil, rapeseed oil and cocoa butter, as well as coconut milk, chocolate, fatty sweets, butter and vegetable fats, make them more susceptible to contamination by MOSH and MOAH for several reasons: [19][20]

- Affinity for Hydrocarbons: MOSH and MOAH are types of hydrocarbons which tend to dissolve well in fats and oils. Lipophilic foods, which are high in fats and oils themselves, have a natural affinity for these hydrocarbons. As a result, MOSH and MOAH can dissolve into these foods and become part of their fat structure.

- Lack of Water-Based Barriers: Water-based foods, like fruits and vegetables, have a natural barrier in the form of water that can prevent the migration of hydrocarbons. In contrast, lipophilic foods have a minimal water content, which doesn't provide the same protective barrier.

- Concentration Effect: Due to their absorption into the fat, MOSH and MOAH concentrations can be more elevated in lipophilic foods.

- Temperature and Moisture: Lipophilic foods are more sensitive to changes in temperature and moisture, which can influence the migration of MOSH and MOAH from packaging materials. High temperatures can cause these substances to migrate more readily into the food.

Under certain conditions involving moisture and temperature, a fraction of the lipids naturally found in various oily and fatty foods, both of plant and animal origin, can convert into free fatty acids (FFA) and unsaponifiable substances.

The deterioration process in lipids occurs through hydrolysis and oxidation.[21][22]

Whilst these free fatty acids (FFA) and unsaponifiable matters are not Mineral Oil Hydrocarbons (MOH), they are considered similar to MOSH/MOAH due to their chemical properties.

6- Case Study: Cashews and MOSH/MOAH

Section content:

- Analyzing Natural Occurrence of MOSH/MOAH in cashews

- How does Cashew Coast mitigate the risk of MOSH and MOAH contamination?

6.1- Analyzing Natural Occurrence of MOSH/MOAH in cashews

Cashews, like all nuts, are a high-fat food. And while they provide a healthy form of fat in with both poly- and monounsaturated fats, their lipid component is susceptible to degradation and transformation into MOSH/MOAH as a result of both hydrolysis and oxidation processes.

In cashews, this deterioration process can happen for a variety of reasons:

- The pericarp of the cashew apple contains tannins, which are polyphenolic compounds that can react with the cashew kernel to produce free fatty acids. The tannins are released during the harvest and can react with the kernel if the cashews are not handled properly. This reaction is more likely to occur in hot and humid weather conditions.

- If the raw cashews are not dried properly, they can become mouldy. Mould, in turn, can produce free fatty acids as a by-product of its metabolism.

- As a result of the reaction of oxygen with the fatty acids in the cashews, oxidation can produce free fatty acids.

- The cashew shell contains a toxin called urushiol. Urushiol is a skin irritant that can react with the cashew kernel to produce free fatty acids.

- The cashew skin contains a bitter compound called cardanol. Cardanol can react with the cashew kernel to produce free fatty acids.

- Cashew kernels can become contaminated with microorganisms. Microorganisms can produce free fatty acids as a by-product of their metabolism.

The natural occurrence of MOSH and MOAH in cashews can be increased by poor processing conditions and can result in rancid smell and unpleasant mouthfeel.

| Production Stage | Sources of FFA | Solutions / Mitigants | |

| Agricultural practices | Cultivation | n.a. | Careful harvesting Dry environment |

| Harvest | Tannins | ||

| Storage & Transport | Storage / Transport | Mould | |

| Processing | Drying (raw cashews) | Mould | Moisture content of the cashews is kept below 8% to prevent mould growth |

| Shelling | Urushiol | Cashew should be shelled carefully to avoid contact | |

| Peeling | Cardanol Microorganisms | Careful peeling of the kernels | |

| Packing & Storage | Package / Storage | Microorganisms | Clean, dry environment Vacuum bags under modified atmosphere |

6.2- How does Cashew Coast mitigate the risk of MOSH and MOAH contamination?

To address the risk of MOSH and MOAH contamination within the cashew value chain, several strategies are employed:

- Selection of Packaging Materials: Opting for packaging materials less prone to containing or releasing mineral oil hydrocarbons serves as a preventive measure to reduce the likelihood of contamination.

- Good Manufacturing Practices: Enforcing rigorous hygiene and manufacturing protocols aids in minimizing the potential for contamination during processing and packaging.

- Regulatory Compliance: Complying with pertinent food safety regulations and guidelines ensures that materials and practices remain within acceptable limits.

- Supplier Audits: Regular assessment and monitoring of packaging material and processing equipment suppliers are crucial to identify and mitigate potential contamination risks.

Additionally, each stage of the cashew value chain is meticulously managed to reduce the risk of contamination.

Ensuring traceability to the farm is imperative for mitigating MOSH/MOAH issues. Cashew Coast stands out as the sole processor in West Africa equipped with traceability to over 14,000 hectares through the implementation of robust SAP Rural Sourcing Management technology.

| Production stage | Cashew Coast Processes to mitigate MOSH MOAH | |

| Agricultural practices | -Evaluation of local pollution levels by our team -Farmer training (*) -Cashews are hand-picked -Food Grade Jute Bags (ICCO standards) (*) |

|

| Storage & Transport | -Food Grade Jute Bags (ICCO standards) -No utilisation of recycled materials -Transport vehicles are cleaned before loading -Sourcing of raw cashew nuts with a moisture content around 10% -Raw cashew nuts are stored in dry conditions |

|

| Processing | Sorting | Rotten, mouldy, and poor quality raw cashew nuts are discarded |

| Drying (Moisture Adjustment) | -Raw cashew nuts are sun-dried in low humidity conditions with adequate ventilation -Moisture content below 10% (ideally 8%) |

|

| Calibration | -Utilisation of food-grade lubricants (H1) -Rotten, mouldy, and poor quality raw cashew nuts are discarded |

|

| Cooking (Heat Treatment) | -Raw cashew nuts are steam-boiled -Then aired in protected conditions for 48hrs to 72hrs |

|

| Shelling | -Utilisation of food-grade lubricants (H1) -Dried cashew nuts are carefully shelled |

|

| Oven Drying (Heat Treatment) | -Cashew kernels are oven-dried (80°C) -Thermal treatment is used as a control point for micro-organisms |

|

| Peeling | -Utilisation of food-grade lubricants (H1) -Utilisation of food-grade cleaning products -Shelled nuts are processed within a week -Cashew kernels are carefully peeled in clean, dry conditions with adequate ventilation -Controlled room temperature -Optical sorting is used as a control point |

|

| Grading | -Extra clean area -Controlled room temperature -Low humidity conditions -Utilisation of food grade material and products -Final inspection is used as a control point -Pasteurisation & Disinfection (IR/UV) -Thermal treatment is used as a control point for micro-organisms |

|

| Packing | -Extra clean area -Low temperature environment -Low humidity conditions -Utilisation of food grade material -Vacuum bags under modified atmosphere (CO2) |

|

| Storage | -No utilisation of recycled materials -Dry & Clean conditions -Temperature kept under 28°C |

|

(*) Cashew Coast Farmer Training aims to address a sector-wide poor practice by providing essential guidance to our traceable farmers. One prevalent issue we've identified is the improper storage of harvested cashews in polypropylene bags. To rectify this, our comprehensive farmer training emphasizes a crucial shift in behaviour: farmers are instructed to abstain from using polypropylene bags altogether. Instead, from the moment they collect the cashews, our traceable farmers utilise jute bags.

7- Sources & References

[1] EFSA Panel on Contaminants in the Food Chain (CONTAM) (2012) Scientific Opinion on Mineral Oil Hydrocarbons in Food. The EFSA Journal, 2012, 10(6):2704. European Food Safety Authority. https://doi.org/10.2903/j.efsa.2012.2704

[2] EFSA Panel on Contaminants in the Food Chain (CONTAM) (2023) Update of the risk assessment of mineral oil hydrocarbons in food. EFSA Journal, September 2023, 21(9). European Food Safety Authority. https://doi.org/10.2903/j.efsa.2023.8215

[3] European Commission, Joint Research Centre, Hoekstra, E., Bratinova, S. (2019) Guidance on sampling, analysis and data reporting for the monitoring of mineral oil hydrocarbons in food and food contact materials. E.Hoekstra & S.Bratinova, editors, Publications Office. https://doi.org/10.2760/208879

[4] European Commission Standing Committee on Plants, Animals, Food and Feed (SCPAFF) (2022) Section Novel Food and Toxicological Safety of the Food Chain. 21 April 2022. Summary report. Health and Food Safety Directorate General.

[5] EFSA (2023) Scientific opinion on the risk assessment of mineral oils hydrocarbons (MOH) in food. EFSA Draft Opinion for Public Consultation. European Food Safety Authority.

[6] EFSA (2023) Discussion paper on the EFSA Draft Opinion for Public Consultation on “Update of the risk assessment of mineral oil hydrocarbons (MOH) in food”. Committee on Toxicity of Chemicals in Food, Consumer Products and the Environment. European Food Safety Authority.

[7] Cravedi, JP, Grob, K, Nygaard, UC and Alexander, J, (2017) Bioaccumulation and toxicity of mineral oil hydrocarbons in rats - specificity of different subclasses of a broad mixture relevant for human dietary exposures. EFSA supporting publication 2017: 14(2):EN-1090. 98 pp. European Food Safety Authority. https://doi.org/10.2903/sp.efsa.2017.EN-1090

[8] Bevan, R., Harrison, P. T. C., Jeffery, B., & Mitchell, D. (2020) Evaluating the risk to humans from mineral oils in foods: Current state of the evidence. Food and chemical toxicology : an international journal published for the British Industrial Biological Research Association, 136, 110966. https://doi.org/10.1016/j.fct.2019.110966

[9] European Commission Standing Committee on Plants, Animals, Food and Feed (SCPAFF) (2022) Section Novel Food and Toxicological Safety of the Food Chain 19 October 2022. Summary Report. Health and Food Safety Directorate General.

[10] Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 laying down the general principles and requirements of food law, establishing the European Food Safety Authority and laying down procedures in matters of food safety. http://data.europa.eu/eli/reg/2002/178/2019-07-26

[11] Council Regulation (EEC) No 315/93 of 8 February 1993 laying down Community procedures for contaminants in food. http://data.europa.eu/eli/reg/1993/315/oj

[12] Regulation (EC) No 1935/2004 Of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food. http://data.europa.eu/eli/reg/2004/1935/oj

[13] EFSA (2023) Margin of Exposure. European Food Safety Authority.

[14] LAV and Lebensmittelverband (2021) Benchmark levels for mineral oil hydrocarbons (MOH) in foods. Länderarbeitsgemeinschaft Verbraucherschutz (Consumer Protection Consortium of the Federal States) / Arbeitsgruppe Lebensmittel- und Bedarfsgegenstände, Wein und Kosmetika (ALB) (Working group on foodstuffs and consumer goods, wine and cosmetics) Lebensmittelverband Deutschland e. V. Food Federation Germany.

[15] Foodwatch (2022) EU proposes limits for mineral oils in food products. Foodwatch.org.

[16] Krettek, A., Thorpenberg, S., & Bondjers, G. (2008) Trans Fatty Acids and Health: A Review of Health Hazards and Existing Legislation. Policy Department Economic and Scientific Policy. European Parliament's Committee on the Environment, Public Health and Food Safety (ENVI).

[17] Ulberth, F. and Wenzl, T., (2019) Analytical approach for checking the compliance of fats and oils against the regulated limit for industrial trans fatty acids (Commission Regulation (EU) 2019/649). JRC Technical Report, Publications Office of the European Union, Luxembourg. https://doi.org/10.2760/102265

[18] Commission Regulation (EU) 2019/649 of 24 April 2019 amending Annex III to Regulation (EC) No 1925/2006 of the European Parliament and of the Council as regards trans fat, other than trans fat naturally occurring in fat of animal origin (Text with EEA relevance.) http://data.europa.eu/eli/reg/2019/649/oj

[19] IFP (2020) Mineral oil hydrocarbons MOSH/MOAH. Institut für Produktqualität GmbH.

[20] SGS () MOSH/MOAH – Questions And Answers. Société Générale de Surveillance (SGS). Sgs.com.

[21] Chasquibol, N. A., Gallardo, G., Gómez-Coca, R. B., Trujillo, D., Moreda, W., & Pérez-Camino, M. C. (2019) Glyceridic and Unsaponifiable Components of Microencapsulated Sacha Inchi (Plukenetia huayllabambana L. and Plukenetia volubilis L.) Edible Oils. Foods, 8(12), 671. MDPI AG. https://dx.doi.org/10.3390/foods8120671

[22] Di Pietro, M. E., Mannu, A., & Mele, A. (2020) NMR Determination of Free Fatty Acids in Vegetable Oils. Processes, 8(4), 410. MDPI AG. https://dx.doi.org/10.3390/pr8040410

[23] Van de Ven B.M., Fragki S., te Biesebeek J.D., Rietveld A.G., Boon P.E. (2018) Mineral oils in food; a review of toxicological data and an assessment of the dietary exposure in the Netherlands. RIVM Letter report 2017-0182. National Institute for Public Health and the Environment. Dutch Ministry of Health, Welfare and Sports. https://doi.org/10.21945/RIVM-2017-0182

[24] Nygaard UC, Vege A, Rognum T, Grob K, Cartier C, Cravedi JP, Alexander J (2019) Toxic effects of mineral oil saturated hydrocarbons (MOSH) and relation to accumulation in rat liver. Food and Chemical Toxicology, 123, 431-442. https://doi.org/10.1016/j.fct.2018.11.022

[25] Ogori, A.F. (2020) Source, Extraction and Constituents of Fats and Oils. HSOA Journal of Food Science & Nutrition. Journal of Food Science & Nutrition. http://dx.doi.org/10.24966/FSN-1076/100060

[26] FSANZ (2018) Mineral oil hydrocarbons in food and food packaging. Food Standards Australia New Zealand. August 2018.